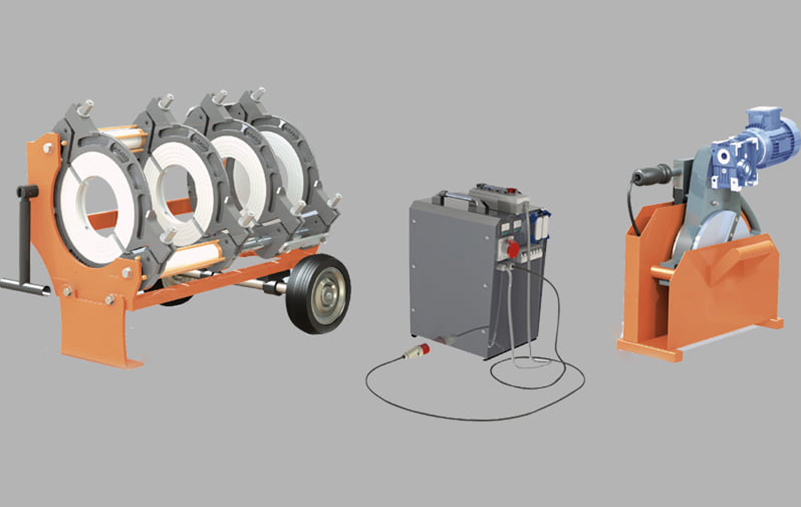

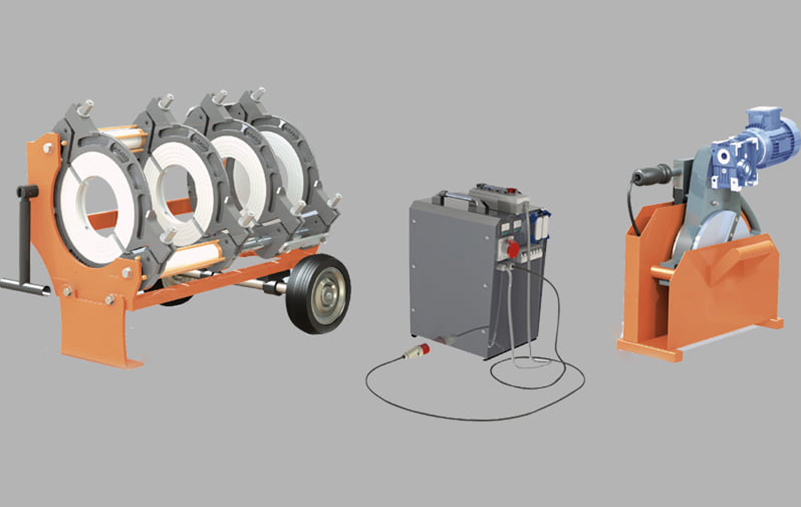

315 Plastic Pipe Hydraulic

Butt Welding Machine

- 160 Manual Hydraulic Plastic Pipe Butt Welding Machine

- 160 Plastic Pipe Manual Hydraulic Butt Welding Machine

- 160 Plastic Pipe Hydraulic Butt Welding Machine

- 250 Plastic Pipe Manual Hydraulic Butt Welding Machine

- 250 Plastic Pipe Hydraulic Butt Welding Machine

- MHW315 Plastic Pipe Manual Hydraulic Butt Welding Machine

- 315 Plastic Pipe Hydraulic Butt Welding Machine

- 400 Plastic Pipe Hydraulic Butt Welding Machine

- 400M Plastic Pipe Single-Phase Hydraulic Butt Welding Machine

- 500 Plastic Pipe Hydraulic Butt Welding Machine

- 630 Plastic Pipe Hydraulic Butt Welding Machine

- 800 Plastic Pipe Hydraulic Butt Welding Machine

- 1000 Plastic Pipe Hydraulic Butt Fusion Machine

- 1200 Plastic Pipe Hydraulic Butt Welding Machine

- 1600 Plastic Pipe Hydraulic Butt Welding Machine

- 2000 Plastic Pipe Hydraulic Butt Welding Machine

- 2500 Plastic Pipe Hydraulic Butt Welding Machine

- 2800 Plastic Pipe Manual Hydraulic Butt Welding Machine

- Used for welding PE – PP – PVDF pipes and fittings with diameters of 90 – 110 – 125 – 140 – 160 – 180 – 200 – 225 – 250 – 280 – 315 mm up to 32 Bar pressure.

- Provides strong, easy, and fast welding with the shortest operational setup in accordance with ISO 12176 – 1 international standards.

- Lightweight design allows for easy handling.

- Designed for a maximum working pressure of 150 Bar.

- Suitable for operation in ambient temperatures between -10°C and +40°C.

W315 Butt Fusion Machine Body

The main body supports the plastic pipes to be welded with two movable and two fixed clamps, ensuring they are secured and centered.

Hydraulic pressure is applied to the system. Two pistons on the carrier shaft move the movable clamps forward and backward, providing the necessary motion for welding.

W315 Butt Fusion Machine Trimmer

Equipped with two rotating blades on both right and left sides, the trimmer is mounted and centered on the main body to clean the pipe ends before heating and prepare them for welding.

The trimmer’s rotary motion is powered by the motor and gearbox group.

The W315 Butt Fusion Machine trimmer unit creates burr-free, parallel pipe surfaces.

W315 Butt Fusion Machine Heater

Heats the pipe ends, which have been trimmed to the desired roughness, with a heating plate to prepare them for fusion welding.

The heater’s temperature is controlled by a digital thermostat located on the heating plate.

W315 Butt Fusion Machine Hydraulic and Electric Control Unit

The electric and hydraulic control unit supplies power to the heater and trimmer and hydraulic pressure to the main machine. It is operated via a handheld remote control.

The remote control has four buttons and one switch. Buttons move the clamps forward and backward, while the switch activates the trimmer.

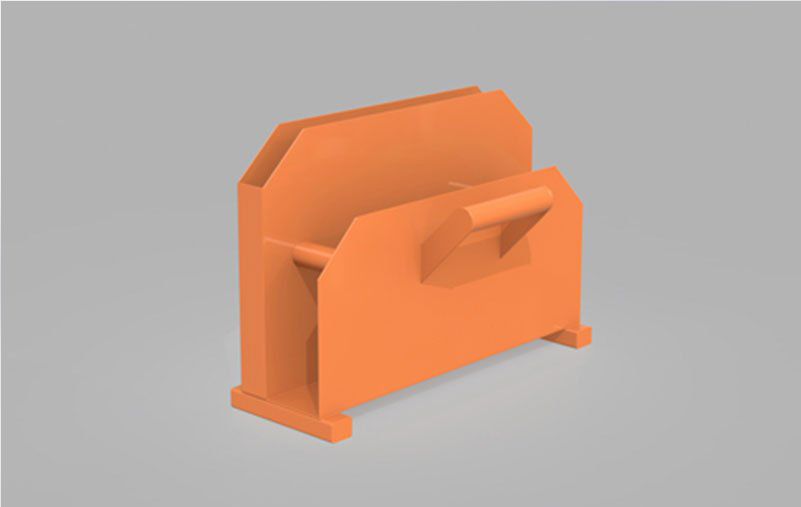

W315 Butt Fusion Machine Protective Case

The protective and support case prevents heat loss from the heater and protects the trimmer and heater from external effects (shock, water, etc.).

| Technical Specifications | |

|---|---|

| Welding Range | Ø 90 mm – Ø 315 mm (Ø90 mm, Ø110 mm, Ø125 mm, Ø140 mm, Ø160 mm, Ø180 mm, Ø200 mm, Ø225 mm, Ø250 mm, Ø280 mm, Ø315 mm) |

| Pipe Types to Weld | PE – PP – PVDF |

| Pipe Max. Pressure | PN32 |

| Heater Electric Power | 220 V – 3.5 kW |

| Trimmer Electric Power | 220 V – 0.75 kW |

| Power of Hydraulic Unit | 220 V – 0.75 kW |

| Electric System | Single Phase |

| Total Electricity Consumption | 4.8 kW |

| Operating Pressure | 150 Bar |

| Required Generator Power | 9 kVA |

| Working Temperature | (-10 °C ~ +40 °C) |

BİZE YAZIN

BİZE YAZIN